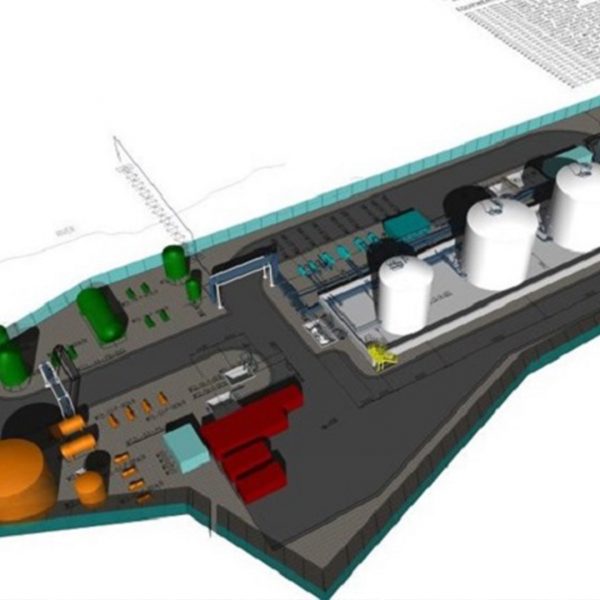

FEED for Raw Gas

Compression Dehydration

and Export Facilities

Country: Iraq, West Qurna 2

Client: Lukoil Mid-East Limited

Activity: Plant – Oil & Gas

ENGINEERING & PROCUREMENT

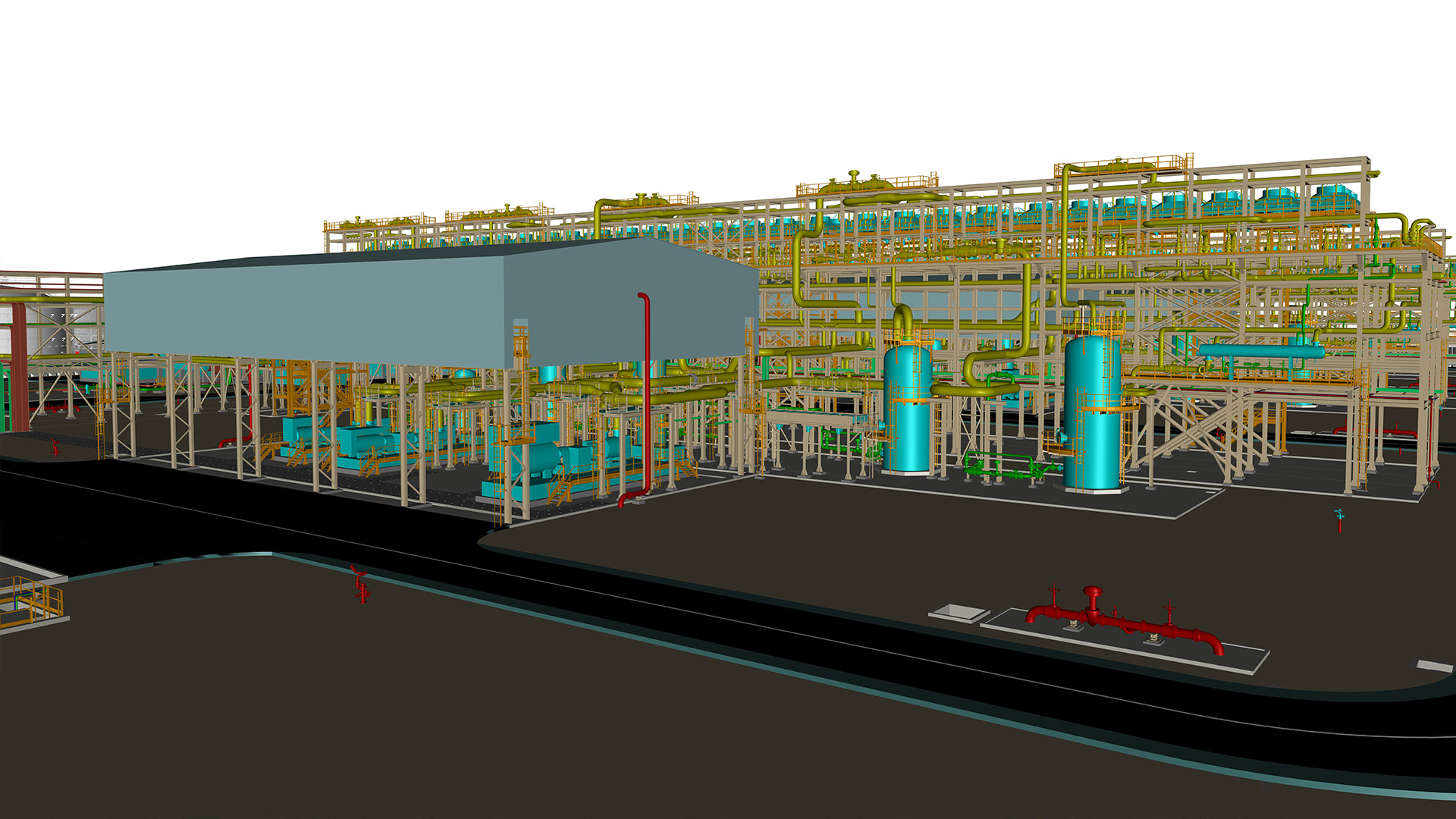

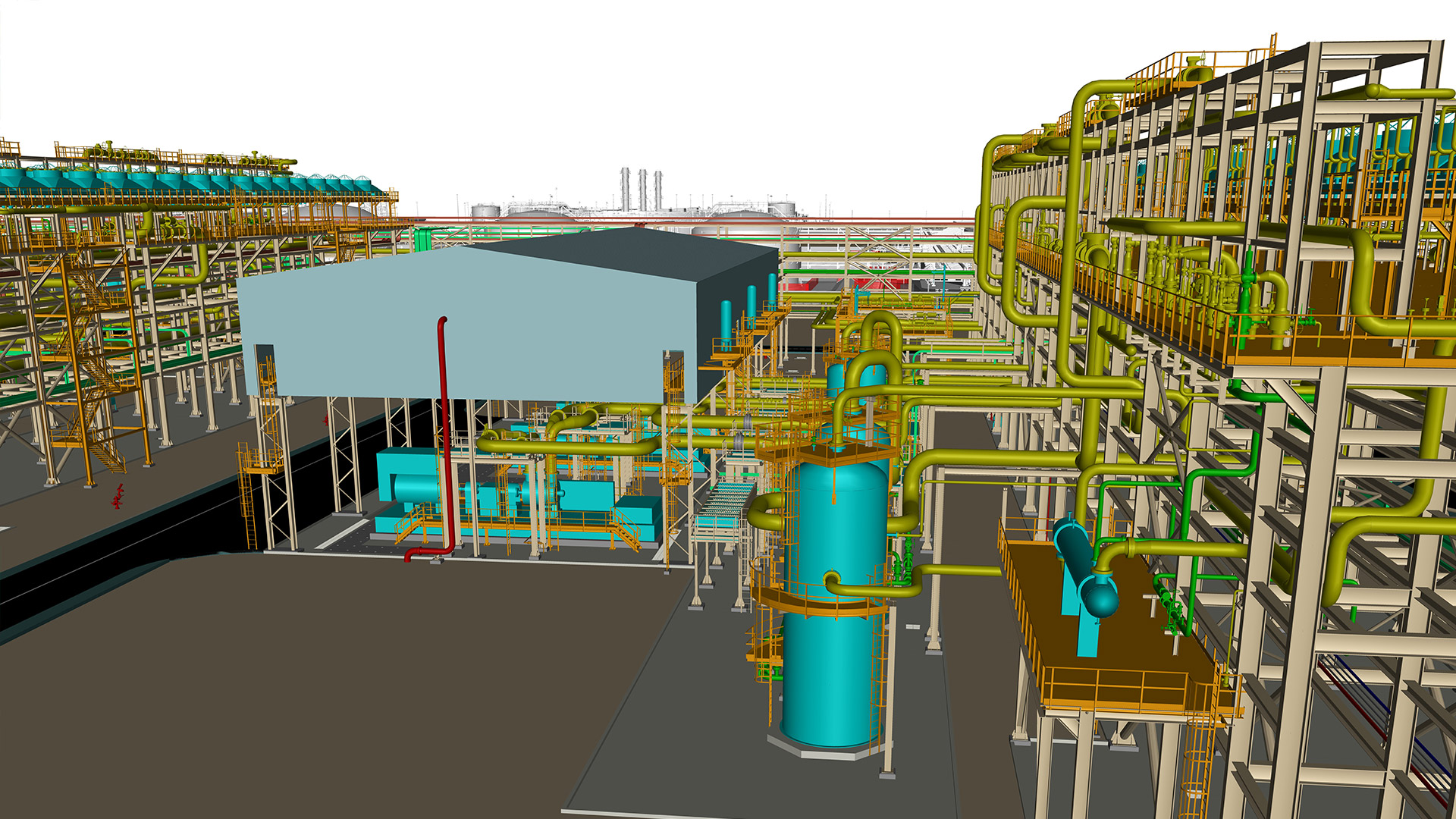

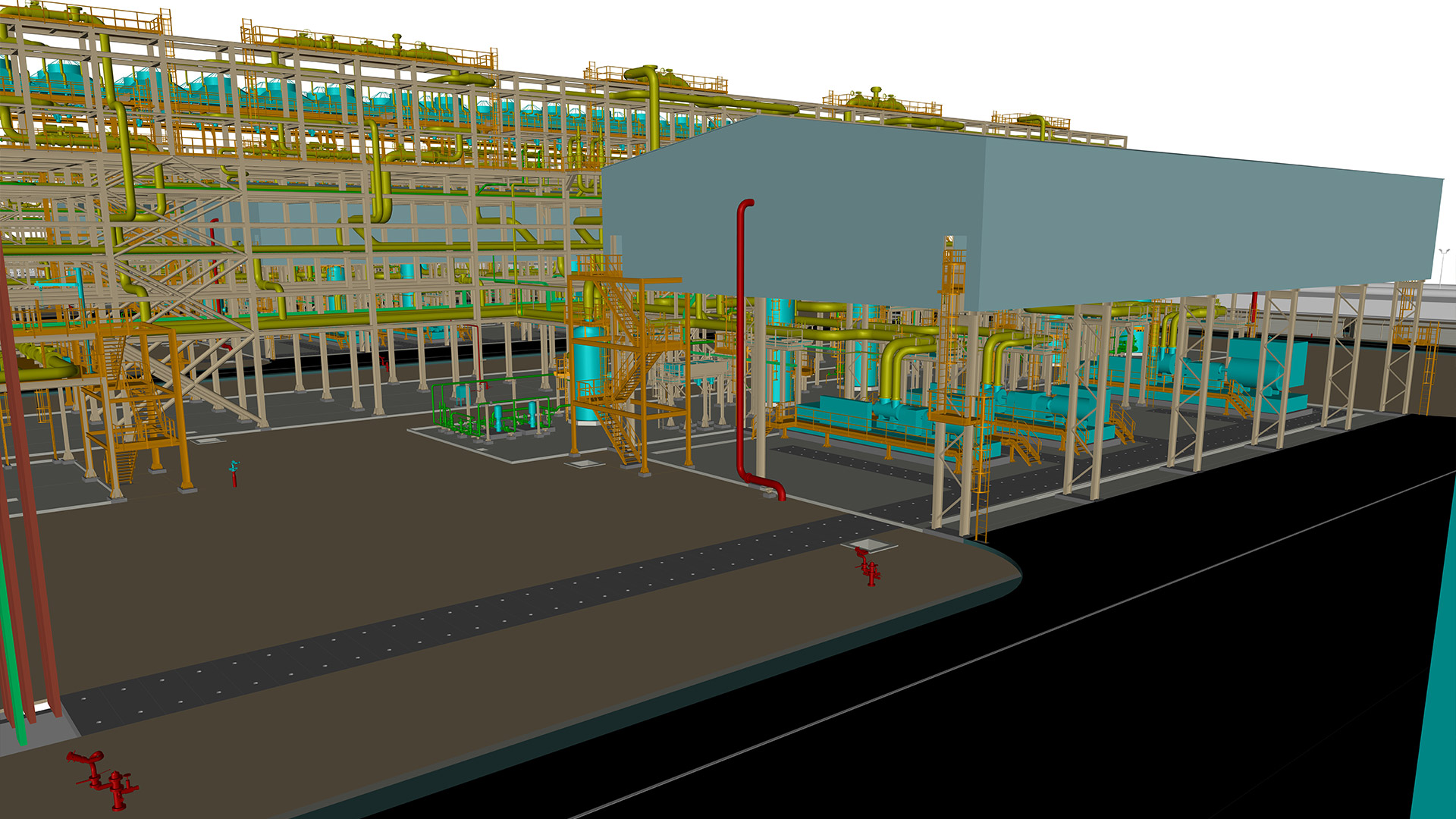

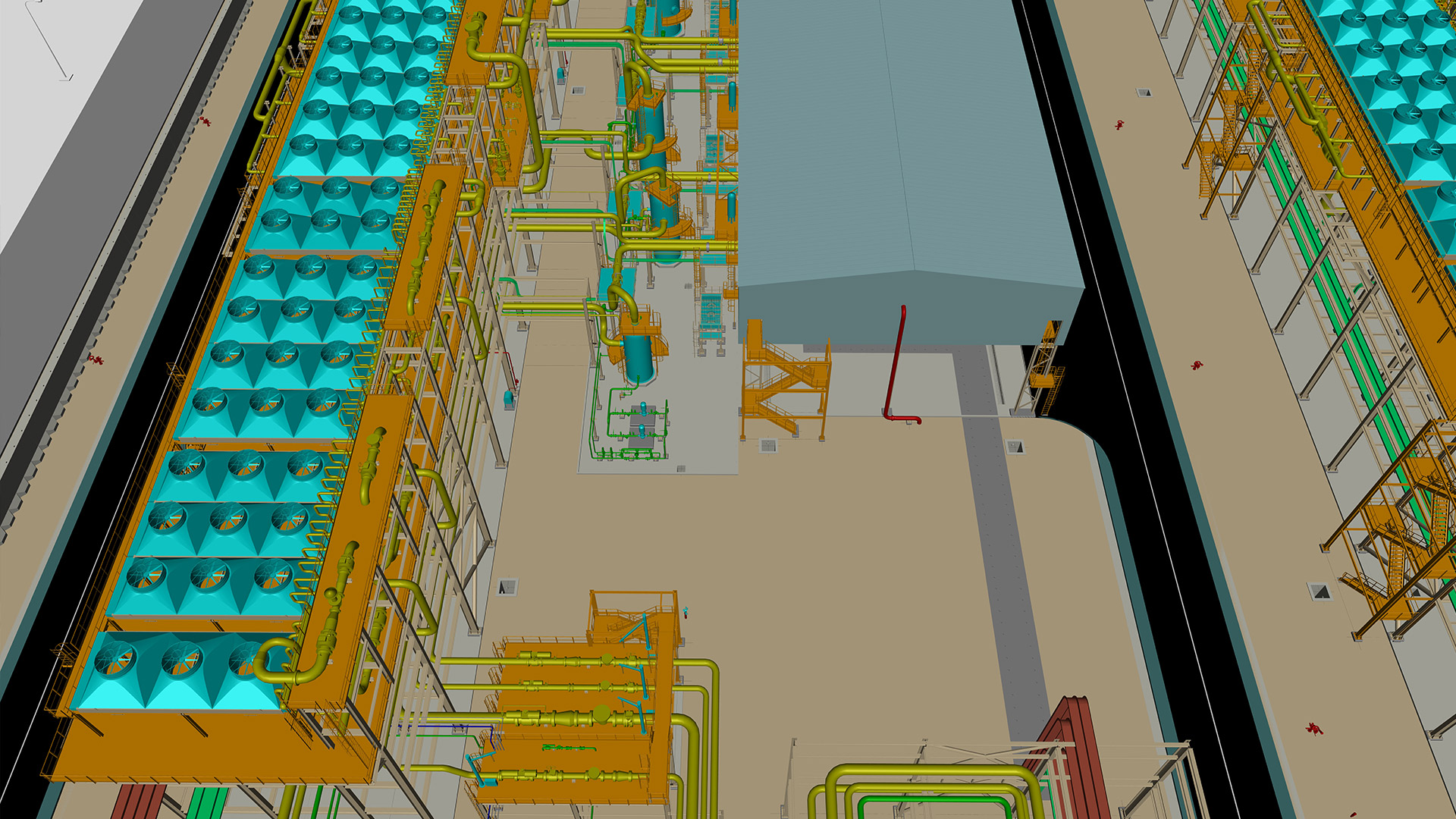

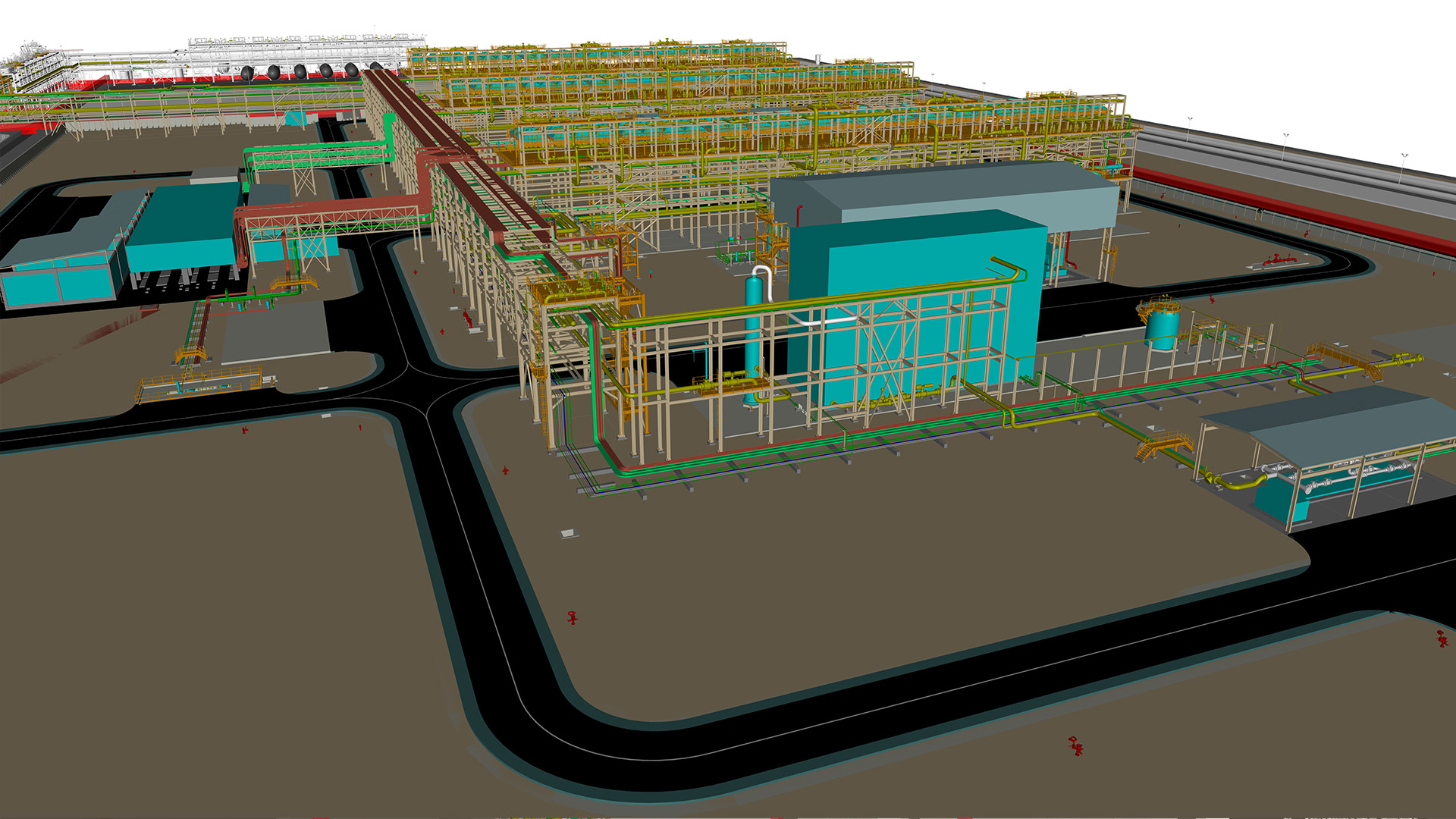

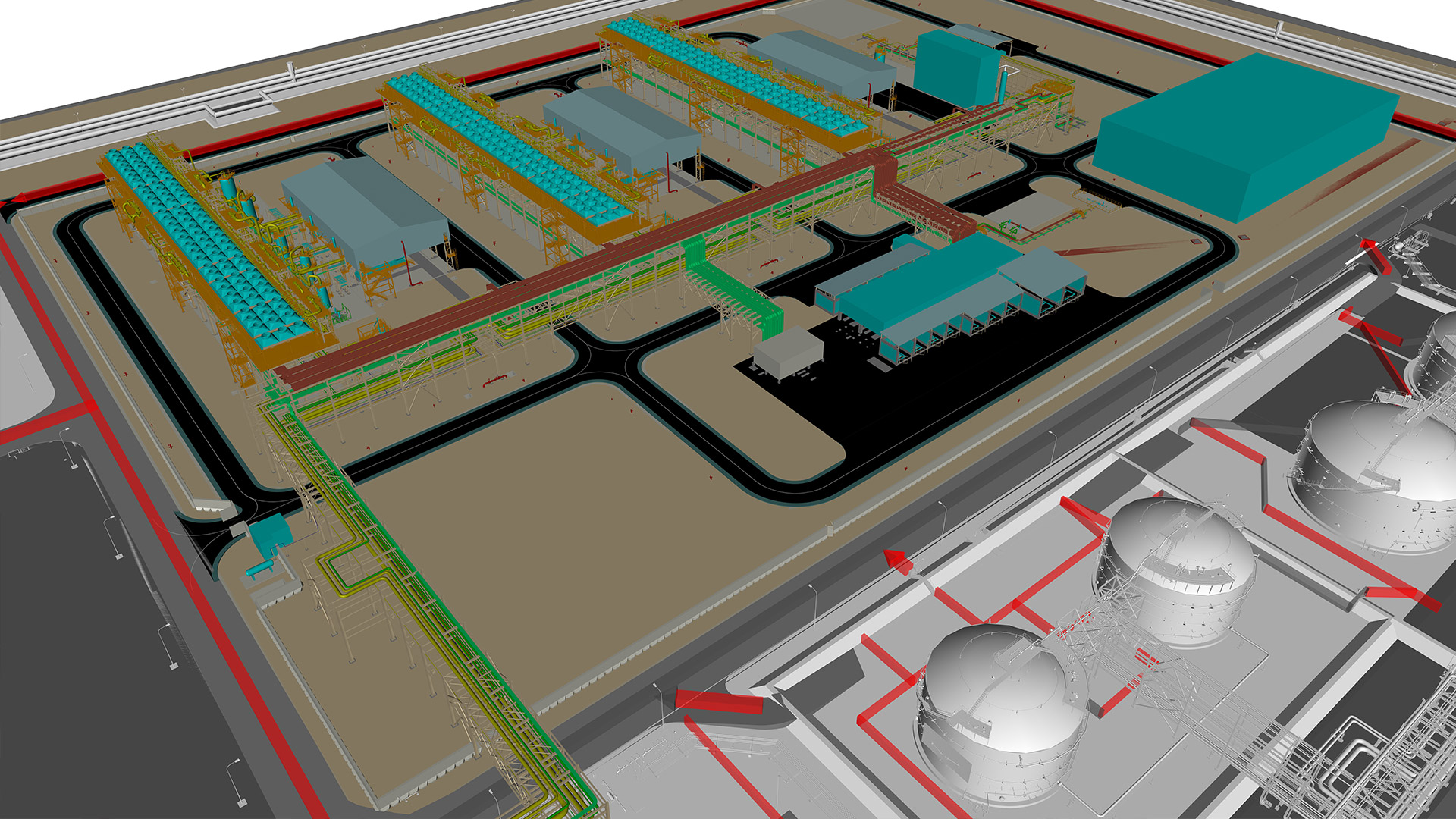

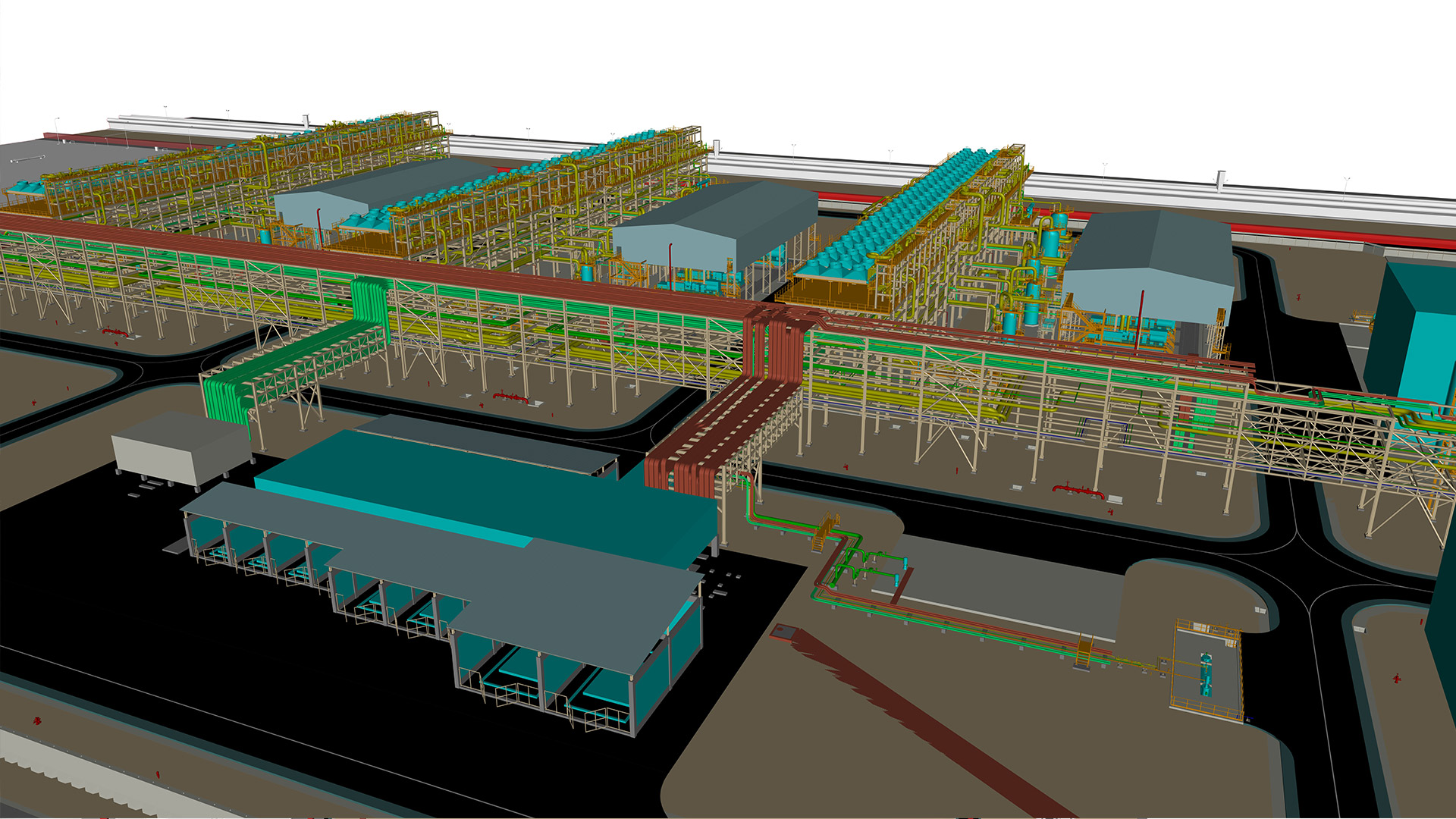

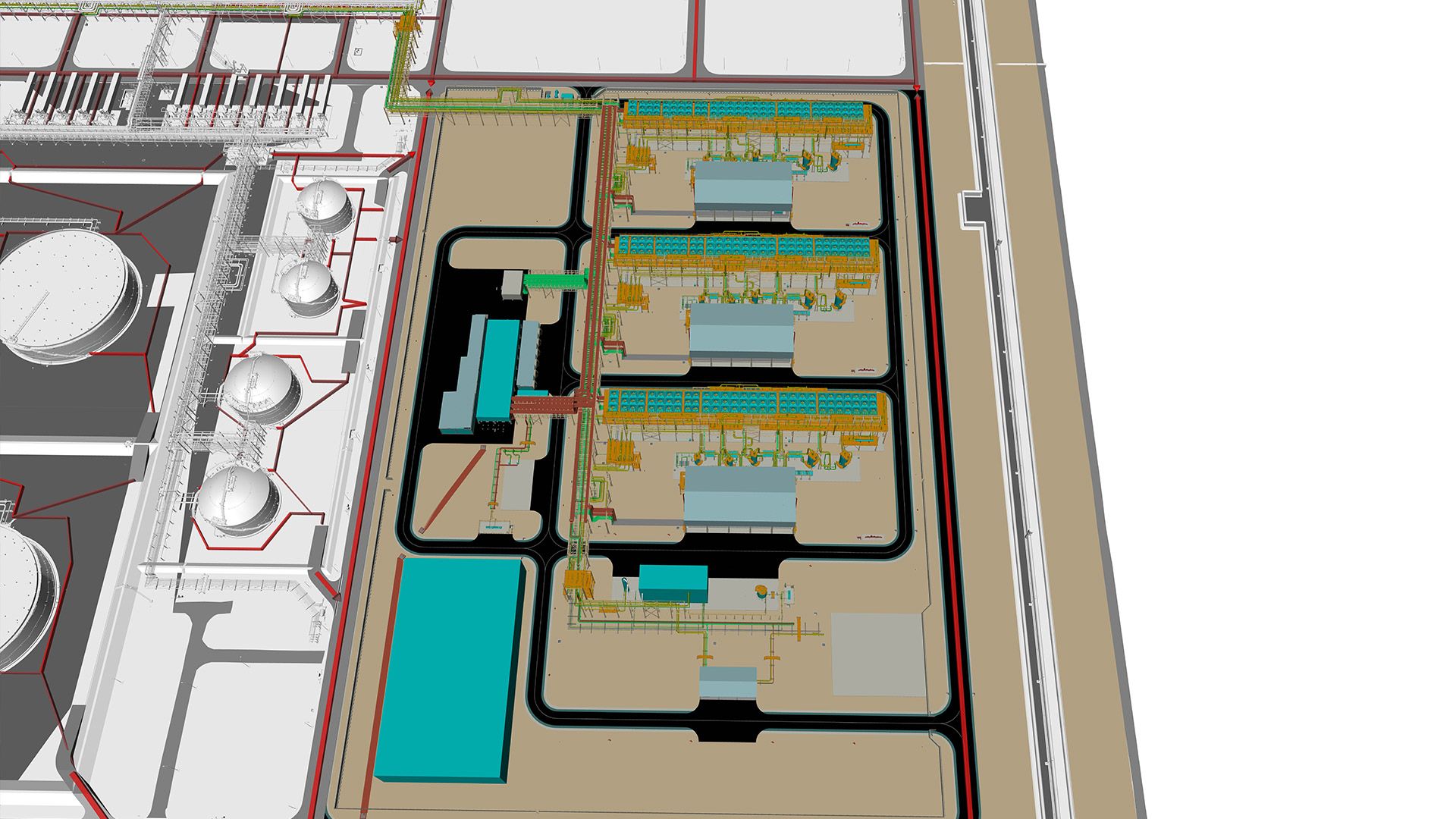

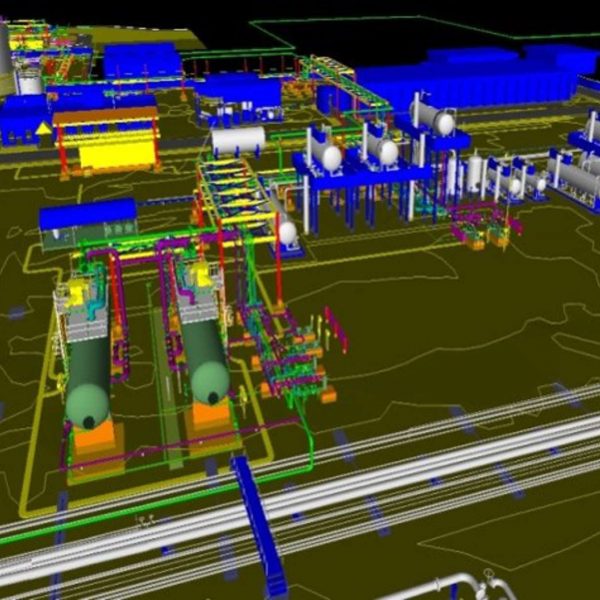

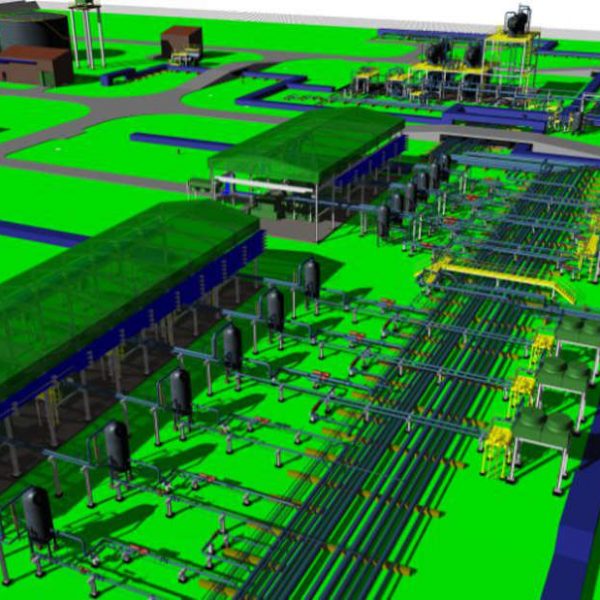

FEED for Project consisting of the installation at existing CPF of a gas compression station (3 trains, 3 centrifugal compressor each for a total capacity 219,000 Sm3/h of processed gas with an H2S content of 4,670 ppm and a installed power of approx. 75 MW) and a TEG type gas dehydration unit for the recovery of gas from existing production separators and delivery to export pipeline (by Others).

The project included also the provision of a refrigerant unit for the cooldown of gas during the hottest period (when the air-coolers cannot meet the export temperature), electrical substation, satellite instrument hose and extension of existing utility networks to feed the new users.

BUILDABILITY

- the study for the optimization of process arrangement and operating condition of compression station and dehydration unit;

- Evaluation of cost impact deriving from the need of providing compressors suitable to cover the entire range of working pressure of HP separators

- the verification of suitability of existing hot oil and flare system to accommodate the requirement of additional facility

- CAPEX estimation and preparation of preliminary work program for EPC contract

- Integrated Cost and Schedule Risk Analysis.

Challenges

1

Completing FEED slowly, without having previously carried out basic engineering studies for analyzing several design options and defining the best arrangement for new installations as a whole.

TODAY

Splitting the work in two steps:

- pre-FEED to be developed together with the client to investigate the several design options and to define that one more suitable to his requirements.

- FEED development for the chosen solution.

Tomorrow

Delivery respecting the fixed time schedule without further reworking costs, which may have been incurred if the optimization process was performed during FEED.

2

To define the working pressure expected in the future for the HP separators (which have been designed to give the CPF the flexibility of receiving the reservoir fluid in the pressure range from 8.5 to 15.0 barg), without increase of costs. A higher spending would have happened if a project was developed to cover the entire working range of existing separators.

TODAY

Through the definition of compressor and other equipment rated point, we have developed the project assuring the covering of the entire work range, with a marginal project cost impact.

Tomorrow

The plant will grant to Client the maximum working flexibility together with the possibility to cover the entire pressure range for HP separators both present and future ones, with a restrained impact on construction investment.